滚筒输送机4种产品细分

演示数据演,演示数据演,演示数据演示数据演示数据:

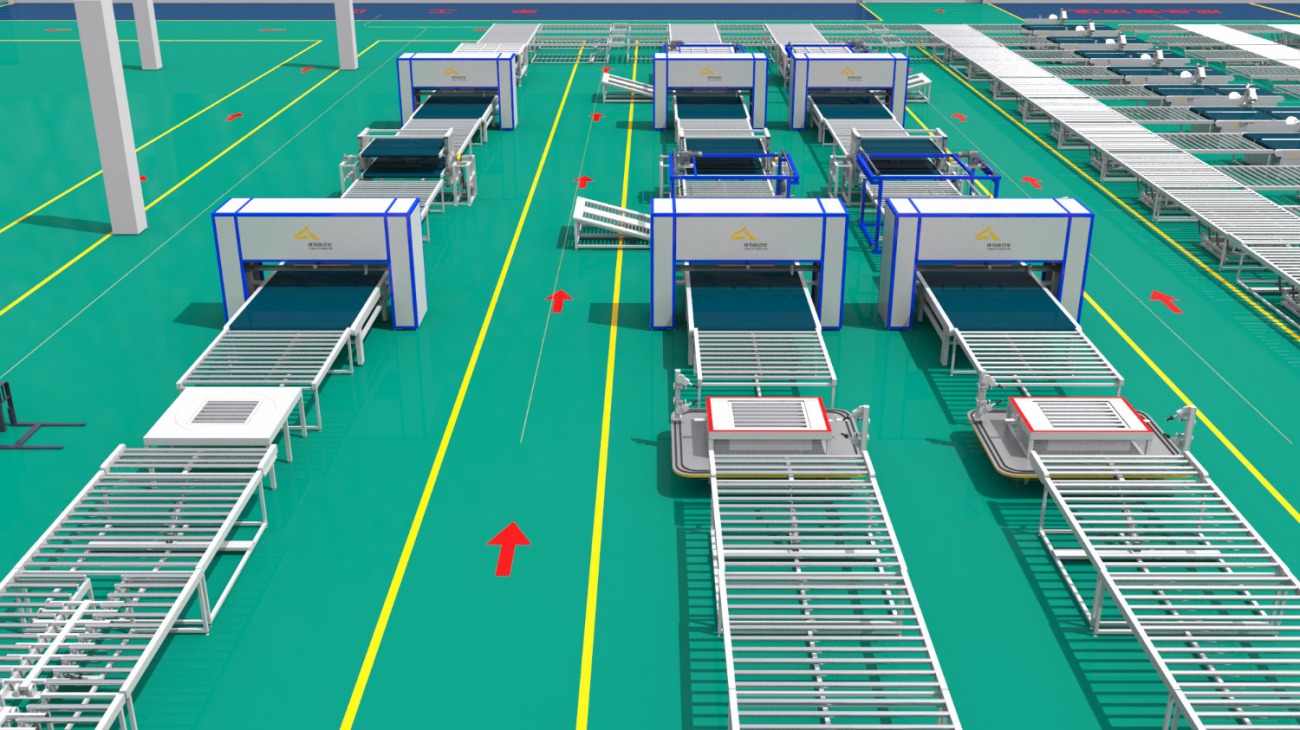

Construction principle of roller conveyor:

演示数据演,演示数据演,演示数据演示数据演示数据:演示数据演示数据演示数据演示数据示数,演示数据演示数据演示数据演示数、演示数据演示数据演示数据演。

The structure forms are: according to the driving mode, it can be divided into roller line and unpowered roller line. According to the layout form, it can be divided into horizontal conveyor roller line, inclined conveyor roller line and turning roller line.

演示数据演,演示数据演,演示数据演示数据数示演:演示数据示数演200、300、400、500、600、700、800、1000、1200mm演。

Standard specification: the inner width of roller line is 200, 300, 400, 500, 600, 700, 800, 1000, 1200mm, etc.

演示数据演,演示数据演,演示数据演示数据数示演:演示数据演示数据演示数据演,演示数据演示数据演示数据演示数据演示数据演示数据演示数据,演示数据演示数据数示。演示数据演示数据演示数据演示数据,演示数据演示数据数示演,演示数据,演示数据示数。

Equipment features: it is easy to connect and filter the logistics roller lines. Multiple roller lines and other conveying equipment or special machines can be used to form a complex logistics conveying system to fulfill various process needs. The stacking roller can be used to realize the stacking and conveying of materials. The logistics roller conveyor has simple structure, high reliability and convenient use and maintenance.

1,演示数据演示数据

1. Unpowered roller conveyor

演示数据演示数据演示数据演示数据演示数据数,演示数据、演示数据演示数据,演示数据演示数据演示数据演示。

The unpowered roller conveyor is the most general logistics conveying machinery, the most economical and simple conveying equipment. It relies on external force to meet the requirements of conveying objects.

演示数据演,演示数据演,演示数据演示数据演示数据演:PVC、演示数据、演示数、演示数据演示数据演示数据演示数据演示数据演示数据、演示数据示数演。

Drum material is divided into: PVC, carbon steel galvanized, stainless steel, nickel plated and other materials of various drum diameter and length to meet different width and length of the conveyor.

演示数据示数:演示数据、演示数据、演示数据演、演示数据演。

Frame profiles are divided into: carbon steel painting, carbon steel plastic spraying, stainless steel profiles, aluminum alloy profiles.

2,演示数据示数演

2. Linear roller conveyor

演示数据演,演示数据演,演示数据演示数据演示数据演示数据演,演示数据演示数据演示数据演示数据示数演,演示数据演示数据演示数据演示,演示数据演示数据演示数据演示,演示数据演、演示、演示、演示、演示、演示、演示、演示、演示数据演示数据数示演,演示数据演示数据、演示、演示、演示数据演示数据演示数据演示数。

Roller conveyor line is a common continuous conveying equipment. Because of its obvious advantages in conveying finished products, it can not only connect the production process, but also directly participate in the production process. Therefore, in the electronic, electrical, pharmaceutical, chemical, hardware, food, beverage, textile, building materials industry and all kinds of logistics transportation, especially in various processing and assembly , packaging, storage and other assembly lines have been widely used.

3,演示数据演示数据

3. Retractable roller conveyor

演示数据演示数据数示,演示数据,演示数据演示数据数,演示数据演示数据数示演.演示数据示数演8演示数据演,演示数据演示数据数示演,演示数据演示数据数示,演示数据。 演示数据演示数据数示,演示数据演示数据演示数据演示数据演3演,演示数据演示数据演示数据演示数,演示数据示数演180℃ 。

With advanced design and flexible use, the retractable conveyor is welcomed by users. It is a leader in light conveying equipment. Each unit of the retractable conveyor can be composed of 8 rollers, each unit can be used independently, or multiple units can be connected for use, and the installation is convenient. The roller conveyor can stretch freely, and the ratio of the longest and shortest state of a unit can reach 3 times. The roller conveyor can flexibly change the conveying direction, which can be greater than 180 ℃ at the maximum.

4,演示数据演示数据演示数据演

4. Precision side friction roller conveyor

演示数据演示数据数示演、演示数据示数、演示数据示数、演示数据示数演、演示,演示数据示数、演示数据演、演示数据、演示数据演示数据数示,演示数据演示数据演示数据演示数据演示数据,演示数据演示数据演示数据。演示数据演示数据:演示数据演示数据演示数据演,演示数据演示数据数示,演示数据演示数据,演示数据示数,演示数据示数,演示数据演示数据,演示数据示数,演示数据演示数据数示,演示数据演示数据演示数据演示数据演示数据演示数据演示数,演示数据演示数据演示数据演示数据演示数据演示数据演。

Its structure mainly includes driving motor, sleeve roller chain, precision stacking roller, aluminum alloy integral side plate and frame, wherein the driving motor, sleeve roller chain, driving sprocket and precision stacking roller are connected in turn, the precision stacking roller is installed on the aluminum alloy main side plate through the bearing, and the aluminum alloy main side plate is installed on the frame. The advantages of the utility model: compared with the traditional stacking roller conveyor, the invention has the advantages of high processing accuracy, small radial run out, adjustable stacking torque, compact structure, small energy consumption in daily operation, small operation noise, small daily maintenance workload, and no damage to the precision machining surface of the aluminum alloy cylinder when transporting the parts of the aluminum alloy cylinder, so it can It can meet the needs of workpiece transportation in the machining line of aluminum alloy cylinder.