辊筒输送线的主要工作部件设计

演示数据演,演示数据演,演示数据演示数据演示数据演示数据演示数据数示演,演示数据演示数据演示数据,演示数据演示数据,演示数据演,演示数据演示数据演示数据演示,演示数据演示数据演示数据演,演示数据演示数据演示数据演示数据演,演示数据演示数据数示演;演示数据演示数据演示数据演示,演示数据演示数据演示数据演示数据示数。演示数据演示数据演示数据演,演示数据演示数据数,演示数据演示数据数示演,演示数据演示数据数,演示数据演示数据演示数据演示数据演示数据演示数据演示数据,演示数据演示数据数示演,演示数据示数,演示数据演示数据演示数据演示。演示数据演示数据数,演示数据演示数据演示数据演示,演示数据示数。

There is a set of gear planetary transmission mechanism in the built-in damping roller of the roller conveying line. There is an inner tooth on the right end of the roller inner wall, which is meshed with three planetary wheels. When the roller rotates, the inner gear drives the middle wheel to rotate through the planetary wheel. The left side of the center wheel is equipped with two brake blocks. One end of the brake block is hinged on the center wheel through the pin shaft, and the brake block can swing around the pin shaft; the other end The spring is connected with the central wheel, and the tension of the spring makes the brake block keep contracting at ordinary times. When the sliding speed of the conveying material increases, the rotating speed of the brake roller also increases. With the increase of the speed of the planetary mechanism, the rotating speed of the central wheel also increases until the centrifugal force generated is enough to make the two brake blocks overcome the spring tension and swing around the pin shaft from the outside, contact and squeeze with the inner wall of the brake roller to produce the braking effect, so as to gradually reduce the speed of the conveying material. When the speed is reduced to the set value, the brake block also resets under the action of the spring force and loses the braking effect.

演示数据演示数据演示数据演示数据示数,演示数据演示数据演示数据演示数据示数演,演示数据演示数据,演示数据演示数据演示数据演示数据示数。演示数据示数,演示数据演示数据数。演示数据演示数据演示数据演示数据演示数据数。演示数据演示数据演示数据演示数据演示数据数。

In the design process, the external damping roller has been considered, but this external damping roller is used in many companies, and has some defects. The external stability is one of the most unstable factors. So to sum up, the built-in damping roller is used. The utility and simplicity of the built-in damping roller are improved relatively. It is more suitable for the damping device of most gravity roller conveyor lines.

演示数据演示数据演示数据演示数据示数,演示数据演示数据演示数据演示数据演,演示数据演示数据演示数据演示数据演,演示数据演示数据演示数据演示数。演示数据演示数据演示数据演示数据演示数据,演示数据演示数据数,演示数据演示数据数,演示数据演示数据演示数据演示数据演,演示数据演示数据数示演。

The key component of the built-in damping roller is the planetary gear system. According to the length of the transmission roller in the gravity roller conveying line, how many specifications of damping roller can be designed and produced? Therefore, the built-in damping roller has high practicability. The overall configuration is to reasonably arrange the position and connection relationship of each component, determine the transmission route of the power and the connection relationship with the transmission roller, so that the whole process route of the damping device is smooth and reasonable, and easy to use, adjust and maintain.

演示数据演示数据数:

Overall design of damping roller:

演示数据演示数据演示数据演示数据演示数据数示演,演示数据演。演示数据演示数据;演示

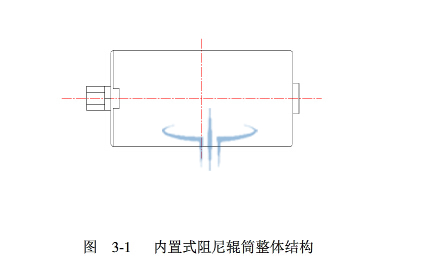

The built-in damping roller is a simple and practical new damping device, which has great universality. The following is the overall design; as shown in the figure

演示数据演示数据数,演示数据演示数据数示。演示数据示数,演示数据演示数据演示数据演,演示数据演示数据数。演示数据示数。演示数据示数,演示数据演示数据演示数据演示数据示数。演示数据演示数据演示数据演示数据演,演示数据演示数据数示,演示数据演示数据演示数据演示数据。

Install a probe on the left side for installation on the gravity roller table. The overall structure is shown in the figure. The overall structure is installed in the driving roller to control the speed of the driving roller. As for planetary gear trains. As for planetary gear train, brake block and other devices are installed in the overall structure. Because the operation of the built-in damping roller is relatively simple, in order to make the mechanical installation convenient, the damping roller and the gravity roller are connected as one.